On National Handloom Day, deep dives into the world of Drapery Silks, where the handloom silk sarees are like an open canvas and the designs speak a contemporary tale.

National Handloom Day: Situated in a quaint town of Arni in Tamil Nadu, Drapery Silks weaves a story of age-old crafts blended perfectly with a contemporary design language.

“Saree is a piece of an open canvas,” expresses Karthik Monju Selvan, co-founder and creative director, Drapery Silks, who along with brother Sunil Prasanth Selvan, director of operations, have been celebrating the six-yards of sheer elegance since 1992, under the able guidance of his father E Selvan, director.

Handloom has played an integral role in the Selvan family. When asked what the craft means to him and his family, Karthik says, “I grew up to the beats of Arni – the sound of Handlooms beating in-sync to rhythmical foot work of the weaver that controls 5000 harnesses in a loom.”

He further adds, “The allure of handloom was so strong that it pulled me and my brother [Sunil] from a well established professional employment, just like it did to my father 40 years ago. My father had to forgo his college education because his parents requested him to take up the handloom craft. It has made us into who we are today.”

The journey of a Drapery Silks Handloom Saree

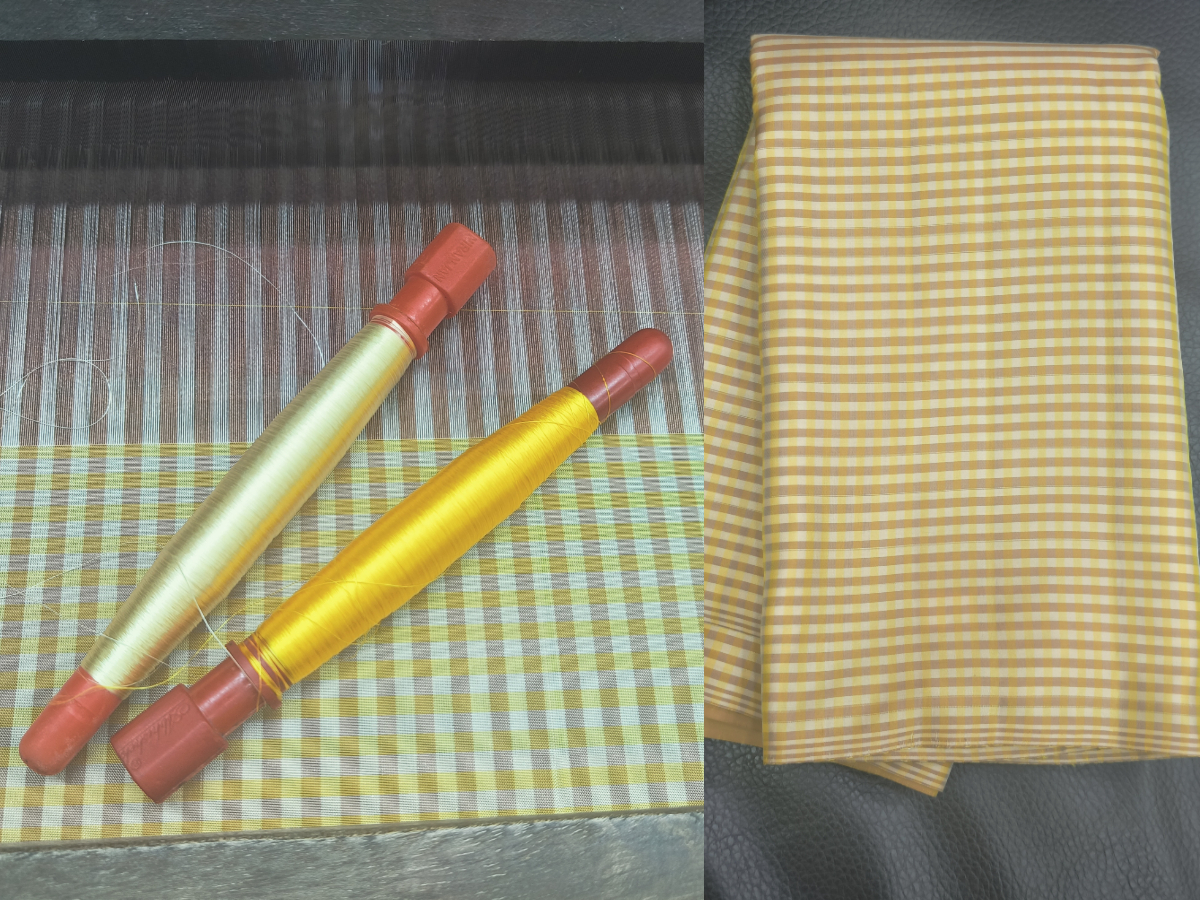

Every handloom saree has a story waiting to be unravelled. At Drapery Silks, every saree is handcrafted with love. Drapery imports its raw silk yarns from Bangalore. Once the yarns are brought to Arni, the yarns are degummed, dyed in colours prepared at their lab, followed by washing of the dyed yarns, gumming, drying and are then colourful yarns are wound and sent to the weavers. At the weavers, the yarn is opened up and stretched on a wooden frame to check for any discrepancies and is later loaded on the loom.

According to Sunil Prasanth Selvan, Drapery has a sustainable approach to the process. Right now, the dyeing station uses Solar power and has reduced the use of diesel by 50 per cent. He is also looking forward to the dyeing factory the Tamil Nadu government will be building to ensure Arni textile companies have one common entity for dyeing yarns. Where right now Drapery dyes 180 kilos per day, the factory will give them an opportunity to dye 200 kilos per day.

The backbone of handloom

Equipped with State-of-the-art looms that place emphasis on weaving efficiency. Having employed 700 personnel involved in handloom weaving, the Drapery family has pledged to protect and promote the handloom ecosystem which includes weavers, the dyers, graphs-man, loom harnessers, jacquard makers, warpers, reed makers and many more of such skilled artisans.

On National Handloom Day, so what about a Drapery handloom saree would you like the world to know? “Our approach towards crafting a handloom saree can be best defined by one word “eclectic”. A collection that best defines this would be our “silver lining collection” whilst fabric is made on an erstwhile Zari by Zari base weave supplemented with silk yarns. The patterns themselves defy normality associated with a silk saree”

Every Drapery Silks saree embraces tradition with modern design sensibilities. From the iconic Last Supper limited edition saree to the larger than life Vrindavan saree, every piece tells a tale of a beautiful past draped in a contemporary style.